Naturally perfect

Nature, as a divine engineer, designed a special form of conservation for each living organism of his creation. Preserving its special qualities to promote its evolution.

Bisignano S.A. designs, develops and builds machines conceived for the evolution of both products and their processing in the food industry. Looking for ways to strengthen their prestige, continuity and growth. Joining your idea and their know-how to reach solutions adapted to your needs.

The food industry needs more and more processes and presentations meeting the highest standards of international quality and competitive capacity.

This is the foundation of Bisignano S.A. which conducts special studies for every customer request, taking into account all specific process details.

Bisignano S.A. finds inspiration in the perfection of Nature to develop materials preserving the essential properties of your products. Based in San Carlos Centro, Santa Fe, Argentina, Bisignano S.A. develops, designs and builds the machines which process and package the products of the most famous national and international food manufacturers.

The company trains its own personnel and the operators at customer sites who entrust their products to the Bisignano technology; for maximum efficiency. Every customer can count on life-ling maintenance services and technical assistance, to avoid any unnecessary production interruptions.

Production lines

Bisignano added a full range of processing machines for food production to its well-known filling machines offering its customers an integral solution in the form of “turnkey” projects.

Bisignano S.A. is a company which understands the concerns of the food processing industry and, besides building standard materials, puts the design department at the service of customers for the development and construction of machines with specific features, according to the needs of every project.

Packaging lines

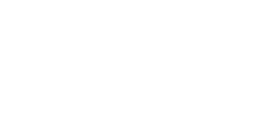

The machines built by Bisignano S.A. meet the most demanding international standards and allow you to benefit from the most recent technological and sanitary advance, including automatic chemical cleaning systems C.I.P. (Clean-in-place), as well as the latest technological innovation in terms of servo motors and robots.

This wide range of machines can be combined to form a full processing line for different types of food products with several packaging alternatives.

More

Filling and Packaging Machines for preformed packaging applications

Rotating filling and packaging machines for trays R - RC – RG

From 2000 to 8000 pieces per hour, suitable for different types of packaging

Linear filling and packaging machines for trays DLB

Up to 40,000 pieces per hour, extendable with several dosing machines and several closing options

Linear filling and packaging machine for trays SIGMA MOTOR CORD

Up to 40,000 pieces per hour, automated with servo motors, designed for different tray forms and with quick conversion to other formats.

Aseptic linear filling and packaging machine for trays SIGNA Aseptic

Up to 40,000 pieces per hour, machine prepared for disinfection of trays and lids by means of Peroxide (H2O2)

Rotative filling and packaging machine for ice cream RH

Up to 6,500 pieces per hour, the machine can handle several packaging types, such as normal trays, cones and carton trays, foil wrapping station, with heat seal and cutting, plastic or carton lids.

Linear filling and packaging machine for ice cream DLB H

Up to 40,000 pieces per hour, the machine can be equipped with ice cream decorator, granulate filling system and toping dosing machine.

Continuous shape

Filling machine for mozzarella MZ 2000

Filling and packaging machines for bottles

Automatic linear filling, sealing and capping machine for bottles RD /B

Up to 3000 pieces per hour, aluminium cap with cutout, screw cap or pressure cap, several sizes possible.

Automatic linear filling and capping machine for bottles DOS /B

Up to 10,000 pieces per hour, the filling machine can be made with filtered air, neck cutting system and automatic cap selector.

Automatic linear filling and capping machine for PET and Glass Bottles PET.

Up to 18,000 pieces per hour, automatic filling and capping machine for 500, 1000 and 2000 g. Volumetric servo dosing, labelling machine, box shaper and packer.

Linear filling and vacuum closing machine for glass packaging.

Up to 4,000 pieces per hour, machine equipped with labelling unit, wash and drying tunnel, filling system, automatic closing machine with vacuum and steam.

Rotative filling system for glass packaging in different shapes RC /F.

Up to 8,000 pieces per hour, provided with structure table, conveyor belt, dosing machine, capping machine and collection table.

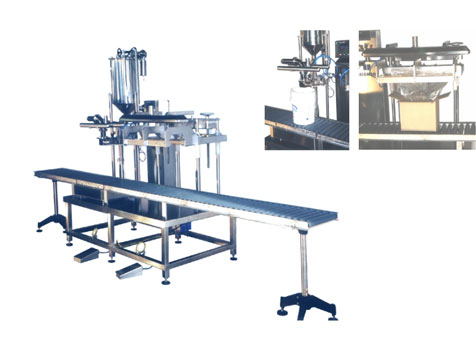

Automatic weight filler for buckets, crates and cartons BA 25.

Production speed depending on the volume to dose, with safety housing, filtered air, filling machine prepared for C.I.P. cleaning.

Automatic weight filler system BA 25 D

Provided with destacking system for buckets, sealing station and lid positioner.

Forming, filling and closing machines

Form fill seal machines for smaller servings BTCN 3x2.

Up to 10,000 pieces per hour, the cup is formed from a flat foil (PS/PTG-PP-PET-PVC, etc.) with a set of format parts for different heights.

Form fill seal machine for small portions BTC 6x2 – BTC 6x4.

Up to 40,000 pieces per hour, the cups are sealed with a top film (soft aluminium, polyester aluminium, polyester paper, etc.) automated with PLC and C.I.P.

Form fill seal machines for customised cups BT

Up to 20,000 pieces per hour, can optionally be equipped with sterilisation system for both base foil and top foil.

Form fill seal machines for cups “decor”

Up to 20,000 pieces per hour, fully automatic system for forming cups and decoration, filler with C.I.P. system, prepared for different presentations.

Thermo form machines BTC & BTC 6C2

Ice cream packaging machines HC1 2000 & RH1 2000

unscramblers, orienters, carton formers and Packers

Automatische Unscramblers

Up to 8,000 pieces per hour, for sorting and feeding bottles with a flat base onto conveyor.

Orienter for plastic bottlers 0B

Up to 14,500 pieces per hour, sorts the packaging by means of a camera system making sure the orientation is correct for the labelling unit or wrapper.

Automatic box former AAC 900/1500

Up to 1,500 pieces per hour, adjusted to form different types of boxes, optional with Hot Melt)

Automatic Tray former AAB 900

Up to 900 pieces per hour, the tray formers can be provided with optional forming parts for different sizes.

Automatic case packer for trays EAB

Automatic case packer for bottlers EABD